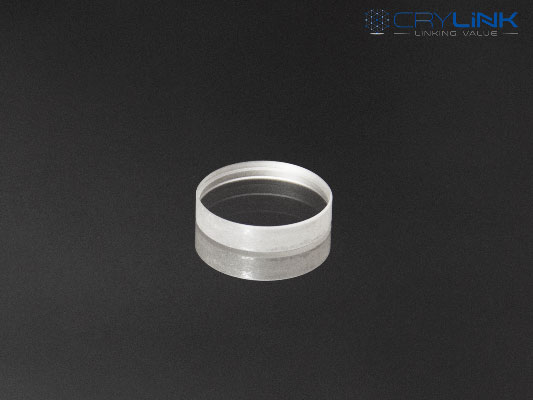

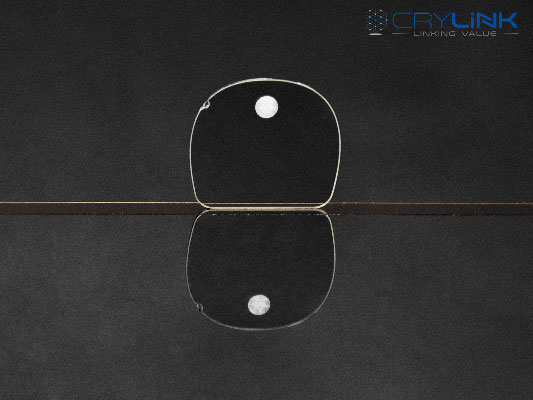

MgAl2O4 Crystal Substrate

MgAl2O4 is an attractive material for uses in a wide range of optical, electronic and structural applications including windows and lenses. Theoretical transmission is very uniform and approaches 87% between 0.3 to 5 microns. Transmission characteristics rival that of ALON and sapphire in the mid-wave IR, making it especially attractive for the ever-increasing performance requirements of current and next-generation IR imaging systems.MgAl2O4 magnesium aluminate (spinel) single crystals are widely used in ultrasonic and microwave material and device related epitaxial growth and as fast IC epitaxial substrates.

It is also found that MgAl2O4 is a good substrate for III-V nitrides device. Spinel (MgAl2O4) is one candidate for such GaN LDs substrate. The crystallographic structure of MgAl2O4 is a spinel type (Fd3m), and its lattice constant is 8.083Å. MgAl2O4 is a relatively low-cost substrate material, which has been successfully applied to the growth of high quality GaN films. MgAl2O4 is cleaved on the (100) plane. GaN LD cavities have been obtained by simply cleaving MgAl2O4 substrates along the (100) direction, which will also work well for ZnO. MgAl2O4 crystal is very difficult to grow, due to the difficulty in maintaining a single phase structure.

Parameter

| Chemical formula | MgAl2O4 |

| Crystal structure | cubic: m3m |

| Lattice parameters | a = 8.083 Å |

| Melting Point | 2130°C |

| Density | 3.61 g/cm3 |

| Transmission Range | 0.21 ~5.3μm |

| Refractive index | 1.8245 @0.8 µm |

| Mohs hardness | 8 |

| Thermal conductivity at 25°C | 14.0 W/(m·K) |

| Thermal expansion coefficient | 7.45×10-6/K |

| Phase velocity | 6500 m/s at (100) shear wave |

| Propagation loss | 6.5 dB/ms |

| Specific heat | 0.59 W.s/g/K |

| Materials | MgAl2O4 |

| Orientation | [100] or [100] or [111] < ±0.5° |

| Parallel | 10〞 |

| Perpendicular | 5ˊ |

| surface Quality | 44474 |

| Wavefront Distortion | λ/4 @632nm |

| Surface Flatness | λ/8 @632nm |

| Clear Aperture | >95% |

| Chamfer | <0.1×45° |

| Thickness/Diameter Tolerance | ±0.05 mm |

| Maximum dimensions | dia 50×100mm |

| Coatings | AR/AR@940+1030 HR@1030+HT@940+AR1030 |

- Good physical,chemical and thermal properties

- Good high temperature properties

- Stable physical performance

- MgAl2O4 subsrate

MgAl2O4 Crystal Substrate have supplied

Leave a Reply