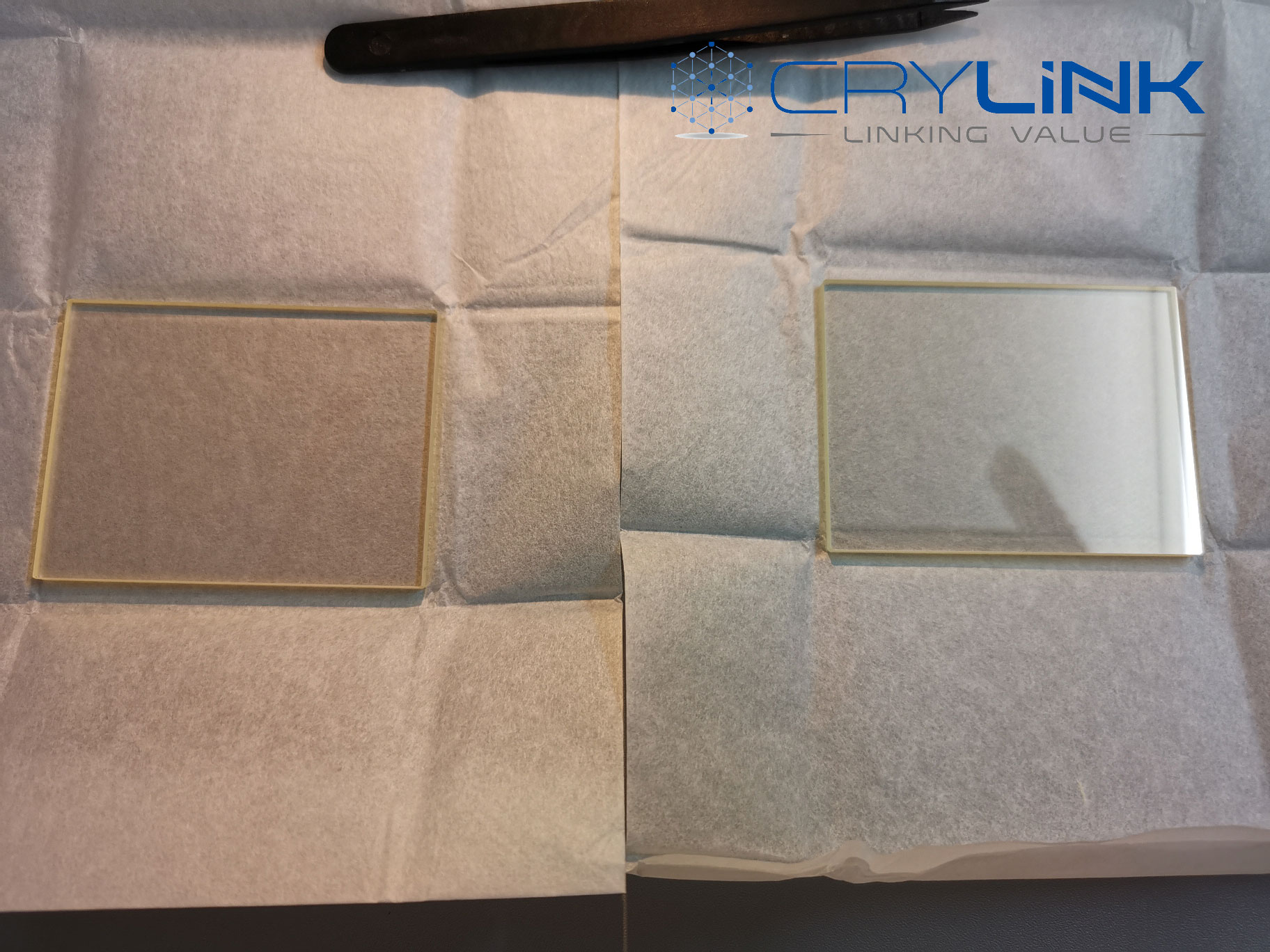

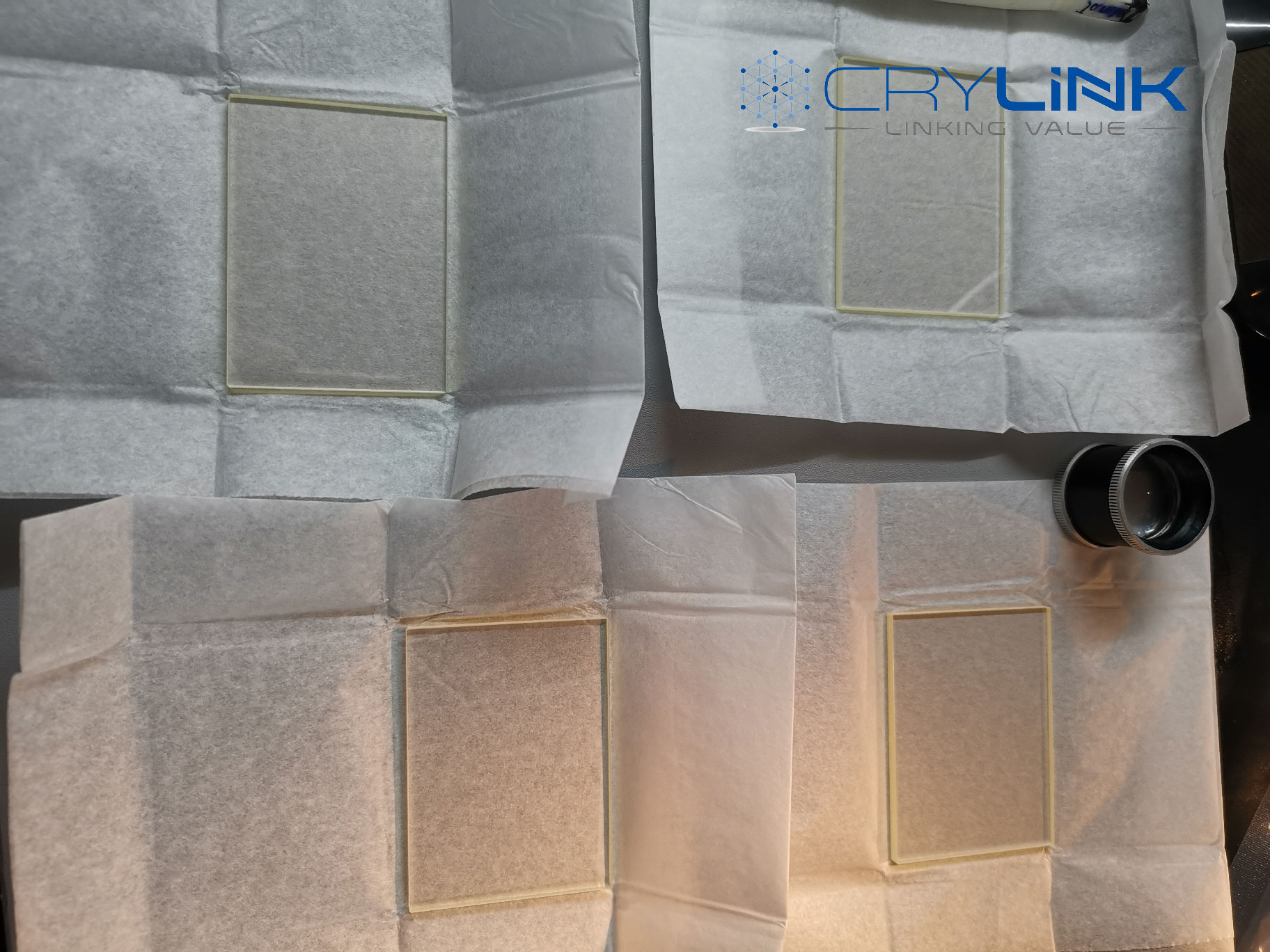

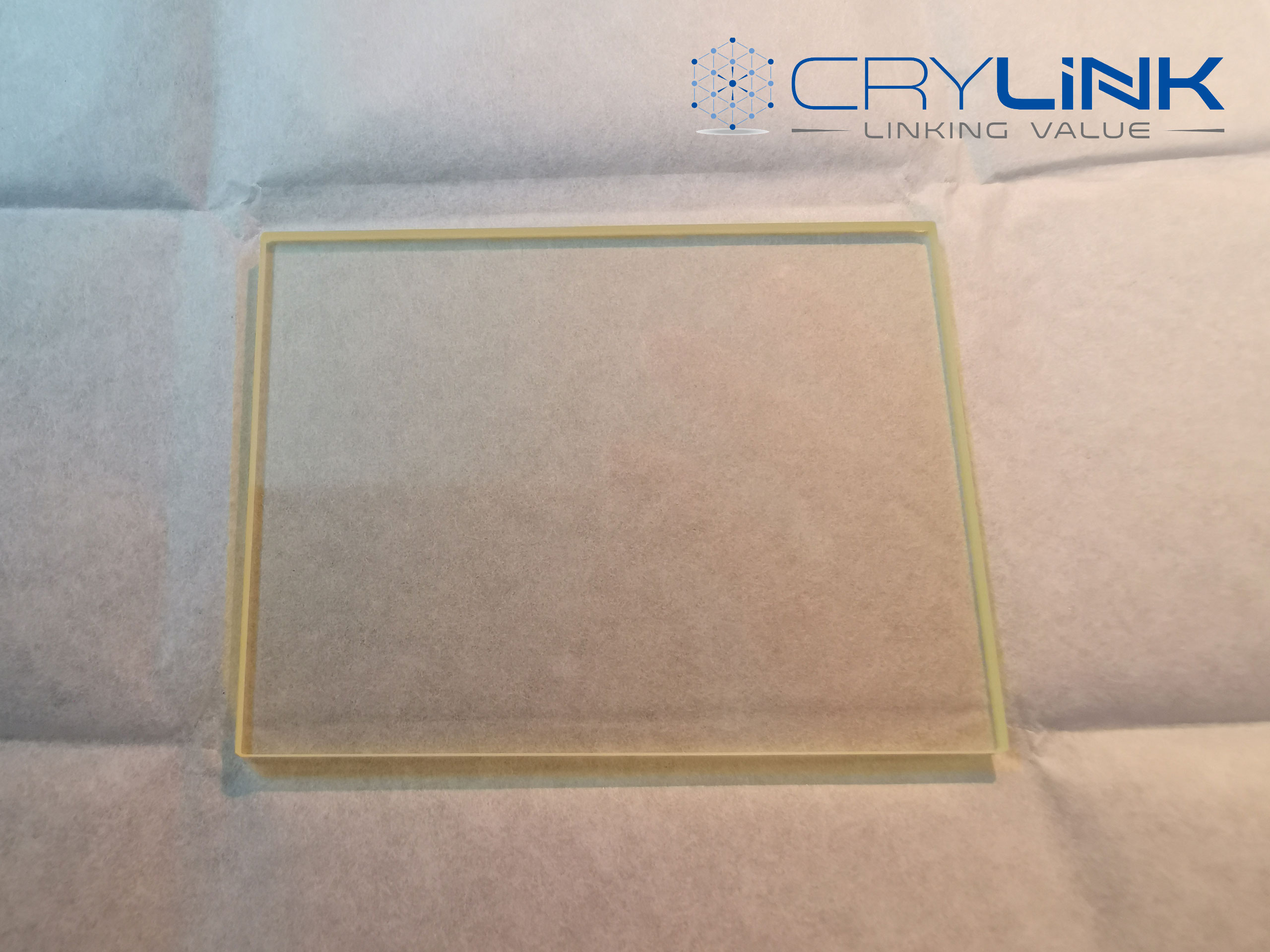

Si Crystal Substrate

Silicon (Si) wafer is a material essential for manufacturing semiconductors, which are found in all kinds of electronic devices that enrich our lives. Few of us have a chance to encounter an actual silicon wafer in daily life. This ultra-flat disk is polished to a mirror-like surface, and made as free as possible of tiny surface irregularities, making it the flattest object in the world. It is also ultra-clean, virtually free of micro-particles and other impurities. These qualities are necessary so it can be used as the substrate material of today’s state-of-the-art semiconductors.

The wafers are ideal substrates for research applications, setup and tool qualification of precision equipment (e.g. steppers & other fabrication processes and semiconductor production requirements. Silicon is exceptionally flat, hard and has very tight thickness, TTV and other dimensional tolerances as well as being bio compatible and radiation hard. Tight tolerance wafers enable a range of technologies such as Si membranes, Si sensors and Si detectors for pressure measurement and MEMS devices such as Si cantilevers for measurement, micro-mechanisms used in energy harvesting, substrates for energy storage, microfluidics including PCR devices, air speed measurement and ultra-precision micro-flow measurements.

Parameter

| Si Properties | |

| Refractive Index | 3.4179 @ 10 µm ; 3,45 |

| Reflective Loss | 46.1 % @ 10 µm |

| Density | 2,3291 g/cm3 |

| Melting Point | 1420 °C |

| Molecular Weight | 28.086 |

| Thermal Conductivity | 1,63 W/(cm K); 1,4 W/(cm K) |

| Specific Heat | 0,703 J/(g K) @ 25 °C |

| Thermal Expansion | 4.05×10-6 / K @ 10…50 °C |

| Hardness (Knoop) | 1150 (Mohs 7) |

| Young’s Modulus | 131 GPa |

| Shear Modulus | 79.9 GPa |

| Bulk Modulus | 102 GPa |

| Rupture Modulus | 340 MPa |

| Elastic Coefficient | C11 = 167 / C12 = 65 / C44 = 80 GPa |

| Dielectric Constant | 13 @ f = 9.37 GHz |

| Si wafer | |

| Diameter | 1inch,2inch,3inch,4inch,5inch |

| Thickness | 0.5mm or 1.0mm |

| Polished | Single or double side polished (SSP or DSP) |

| Orientation | <100>,<111>,<211>,<311>,<411>,<511>,<711>,<911>,<110>,<210>,<310>,<510>,<531>,<731>,<910> |

| Redirection Precision | ±0.5° |

| Angle of Crystalline | Special size and orientation are available on demand |

| Special Specification | We can customize specific orientation and dimension upon requirements |

- High quality single crystal

- High hardness

- Good mechanical properties

- Good physical and chemical properties

- Electronic parts and components

- Semiconductors

- PCR devices

Si Crystal Substrate have supplied

Leave a Reply