Just another WordPress site

Just another WordPress site

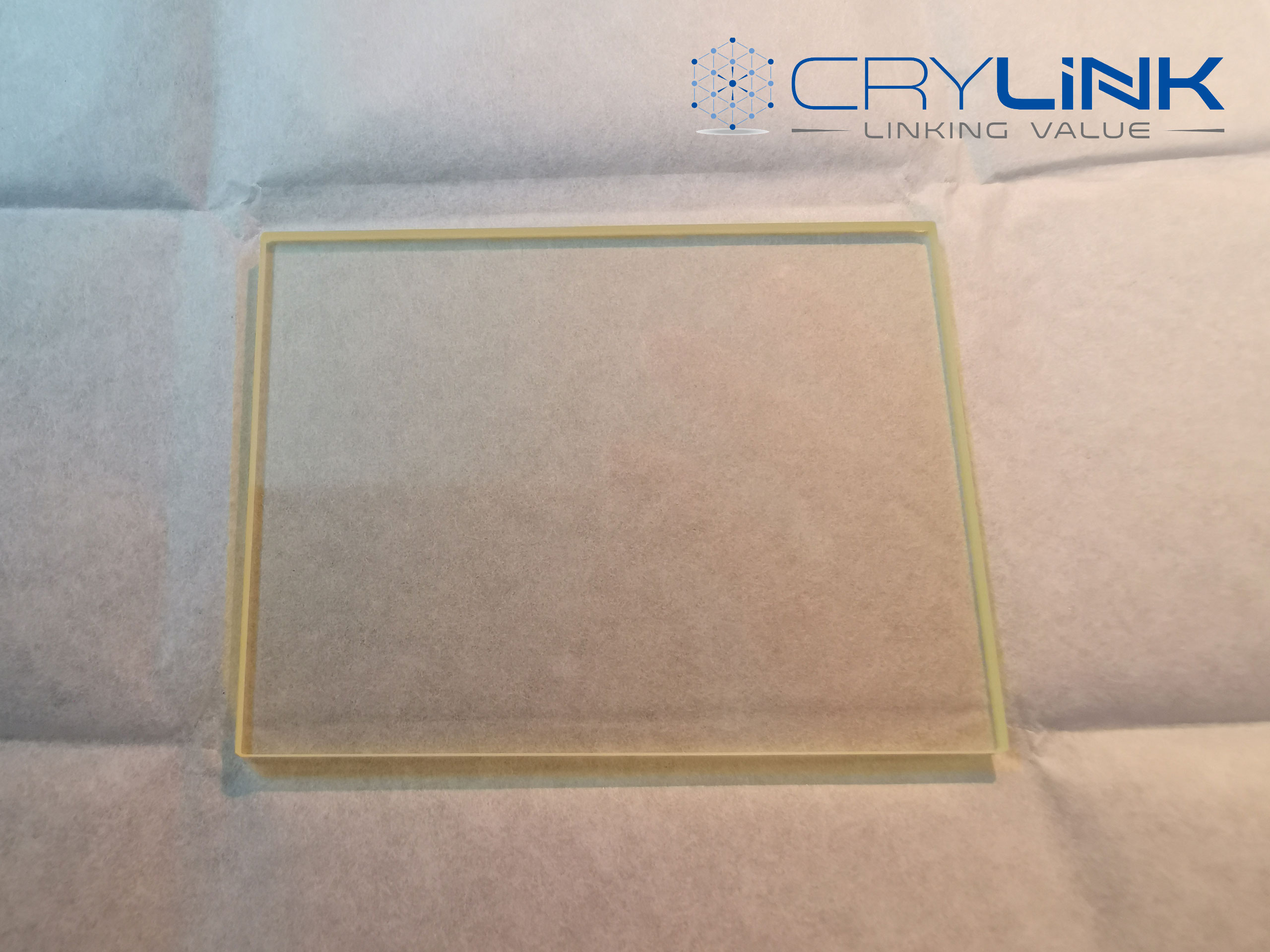

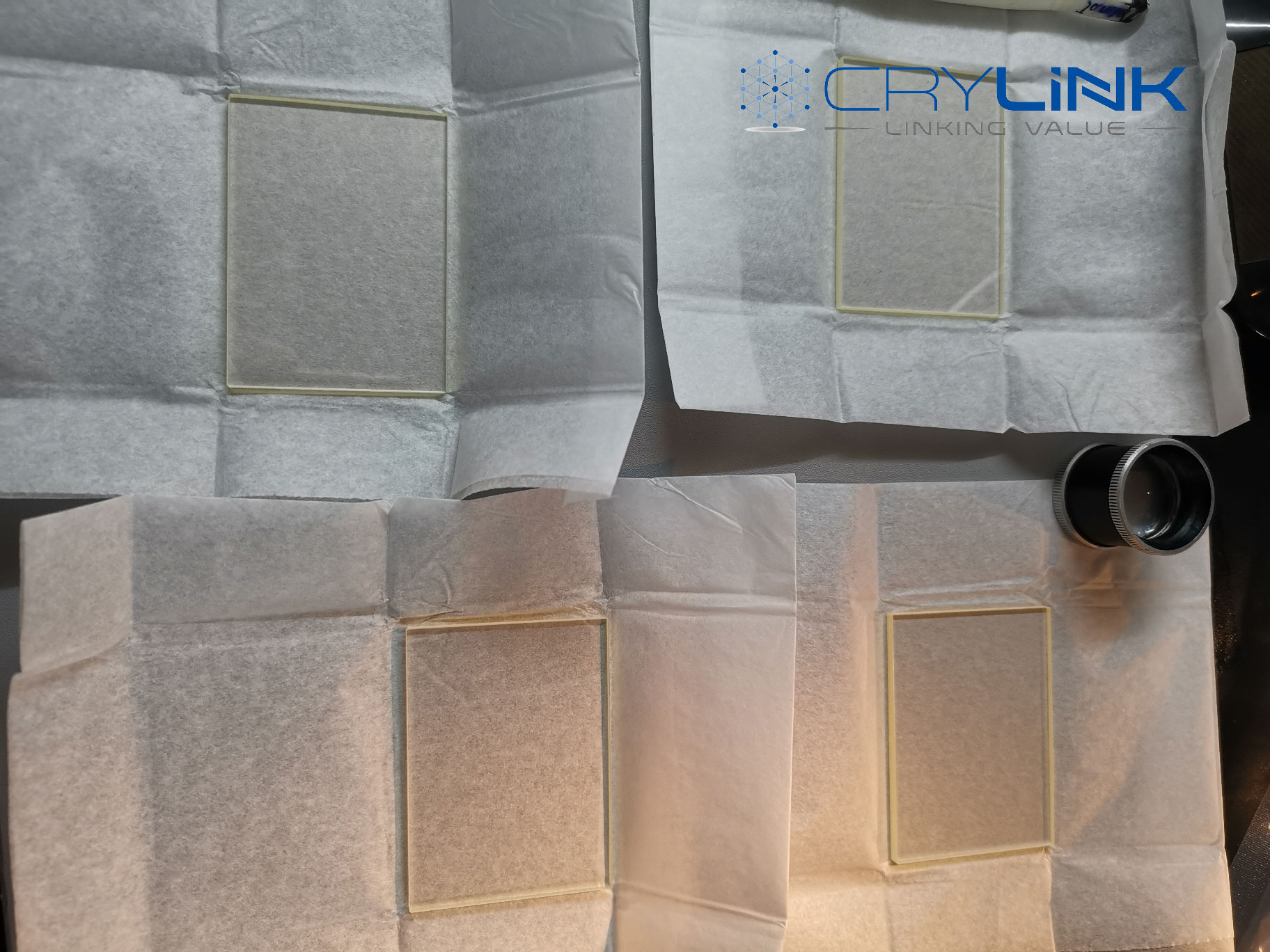

Al2O3 substrate is one of the most popular ceramic substrate which has excellent heat resistance, high mechnical strength, abrasion resistance and small dielectric loss. The surface of alumina substrate is quite smooth and low porosity, 99.6% alumina substrate is suitable for thin film device, 96% alumina substrate is suitable for thick film device application.

Alumina Oxide (Al2O3) is a readily available material with reasonable processing cost, possessing excellent mechanical, electrical, and wear properties. Alumina Substrates have a wide range of applications, including thin film and thick film microelectronic , high power and high frequency circuit RF/microwave components and capacitor or resistor. Furthermore, the porous alumina substrates are often used as sintering base with the thermal treatment of LTCC, piezo-ceramics, SOFC-electrolytes, dental ceramics and metallic materials to 1500℃.

| Chemical formula | Al2O3 |

| Color | white |

| Density | 3.72g/cm3 |

| Thermal conductivity | 22.3W/m·K |

| Thermal Expansion ( x10-6/℃) | 8 |

| Dielectric strength | 14E6 |

| Dielectric Constant (at 1MHZ) | 9.5 |

| Loss Tangent (x10-4@1MHZ) | 3 |

| Volume Resistivity | >1E14 ohm-cm |

| Diameter | Ø 1″ / Ø 2″ / Ø 3″ / Ø 4″ |

| Square size | 10 x 10 / 20 x 20 / 50 x 50 / 100 x 100 mm |

| Thickness | 0.4 mm / 0.5 mm / 1 mm |

| Surface | As fired one side polished / two sides polished |

| Roughness | Ra <= 0.3μm |

Leave a Reply